This week, we sat down to talk about his journey—from bootstrapping his first company, to leading ventures in test and measurement, and now building Glue.

Background & Experience

Early Career & First Companies

I started out as a software engineer at a SaaS health and safety company in Nashville. Not long after, I moved across the street to a credit card processing company that was in the middle of being acquired. That experience and two colleagues who would later become my co-founders pushed me deeper into startups.

I was obsessed with writing high-quality software, test-driven design, and cybersecurity. So I bootstrapped my first company, focused on helping organizations build a stronger software culture—one where secure, well-tested code was the default, and behavior-driven development kept teams from overengineering.

After a successful exit, I jumped to the opposite end of the startup spectrum launching a venture-funded company from day one. This time, the focus was on harnessing mobile video trends to reinvent how smartphone users told stories through video.

I only realized later how valuable it was to see both sides: a bootstrapped, profit-driven tech company and a venture-funded, growth-at-all-costs one. That contrast shaped how I’d approach future startups: understanding the tradeoff between control over the roadmap and the raw speed that venture funding provides, and how to strike the right balance.

Ventures into Test & Measurement

When I met my co-founder at Initial State, he had just spun some intellectual property out of Lexmark on embedded logic analyzers for custom microprocessors. My background in high-scale cloud computing and his in ASIC design made for an interesting match. As we traded notes, we kept coming back to the same problem—how engineering teams debug complex systems and why so many existing tools fell short.

We eventually scrapped the ASIC IP but held onto what mattered: the core methodologies behind analysis and debugging. Instead of building hardware, we launched a SaaS product designed to make time-series data easy to understand and share. With more devices coming online and systems growing more complex, we saw an opportunity to create tools that helped engineers “see what happened” and communicate it smoothly. As we built out the backbone for data streaming and scaled our enterprise solution, an acquisition offer came our way, setting off a chain of events that led us to Tektronix.

At the time, I was new to the test & measurement industry, but it seemed obvious that things were due for a shift. Ubiquitous connectivity and increasing bandwidth weren’t just making data more accessible—they were unlocking entirely new ways to generate insights in real-time. The kind of data Tektronix had built its legacy on could be used to drive deeper, faster analysis, making problem-solving more intuitive.

I stayed on as we kept pushing forward on this vision, and now being part of a large conglomerate gave me a front-row seat to the sheer complexity of building high-tech products. Along the way, I was introduced to the Japanese concept of “gemba,” the idea that to truly understand a problem, you have to go where the work is happening.

I saw firsthand how engineers wrestled with the vast and often cumbersome tools required to push hardware innovation forward. It was a reminder that the best solutions don’t just solve technical problems; they make the hard parts of engineering a little easier.

Glue

These customer pain points and market shifts led to my latest startup, Glue. It began as an idea we incubated within Tektronix/Fortive, in partnership with their enterprise innovation arm Pioneer Square Labs. Glue’s mission is to transform product realization by giving engineers better tools to measure, validate, and verify designs—bridging the gap between hardware product design and production-ready manufacturing.

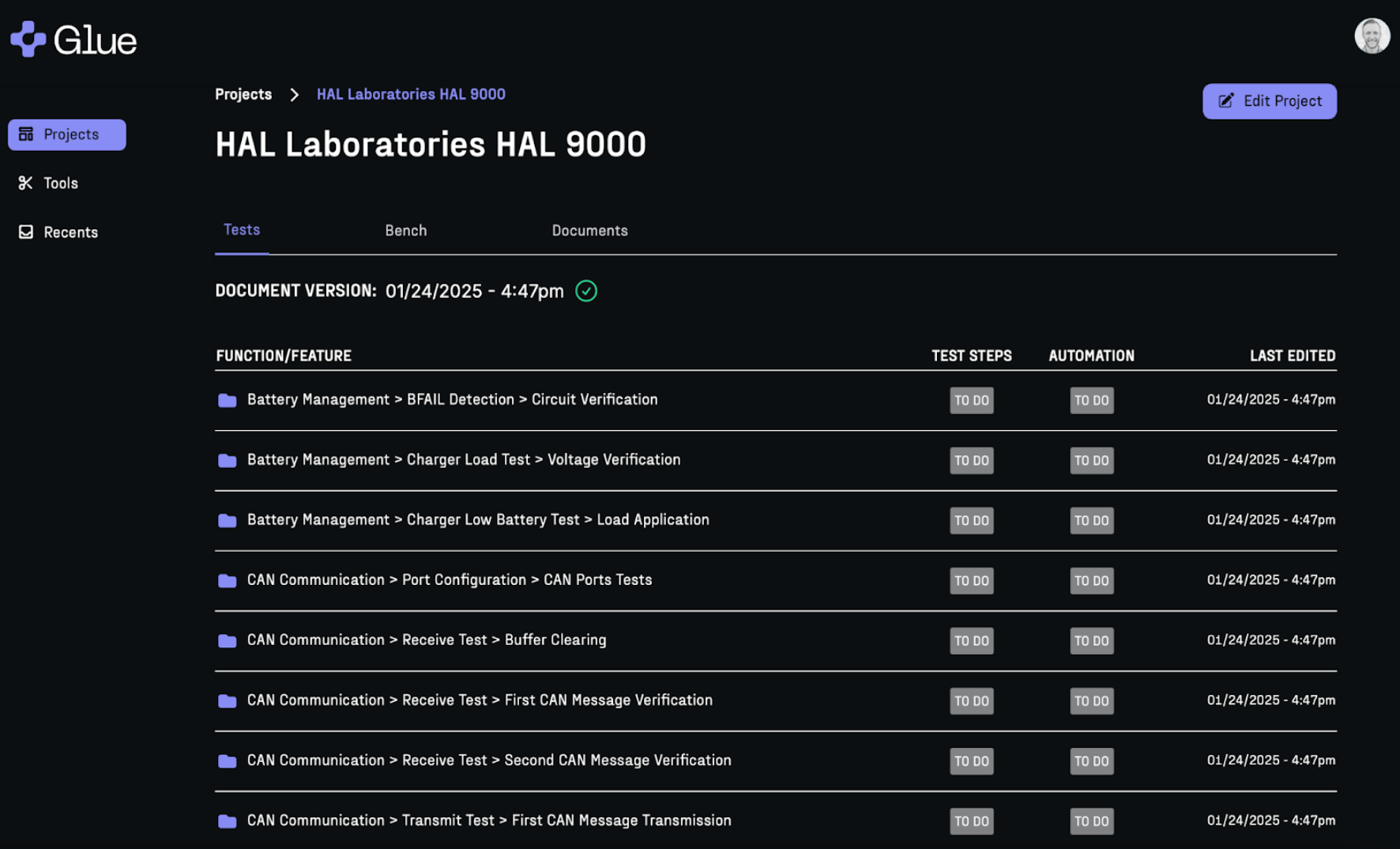

Our first product rethinks how test plans and procedures are developed. In product development, engineers start with product designs and specifications (what it should do, and what problems it must solve) to research and development (how it should be done and what’s technically possible). Validation comes next, ensuring the product meets its requirements before it can be produced.

Ensuring a product meets specifications, compliance requirements, and design constraints is often a shared responsibility across many engineering and product teams. Guaranteeing that it performs as expected, under all designed conditions in a repeatable way, typically falls to test and validation engineers. The best teams have specialists dedicated to this, but in reality, many engineers juggle multiple roles. Where this becomes a real challenge is when a product’s complexity or performance characteristics require commensurately complex equipment to acquire signals, measure responses, and test thresholds while also supplying the appropriate loads or supplies to produce real-world integrations.

Setting up and using these instruments is practically a discipline of its own. Dedicated test engineers spend years mastering them, but most engineers don’t have the time. And that’s only part of the problem. The product development timeline assumes there’s plenty of space for testing and validation before launch, ignoring the reality of design changes, rework, and fast iteration cycles. Complex product specs, intricate measurement systems, and rigid validation workflows slow you down at best—and at worst, they lead to overengineering, in-field failures, and missed launch windows.

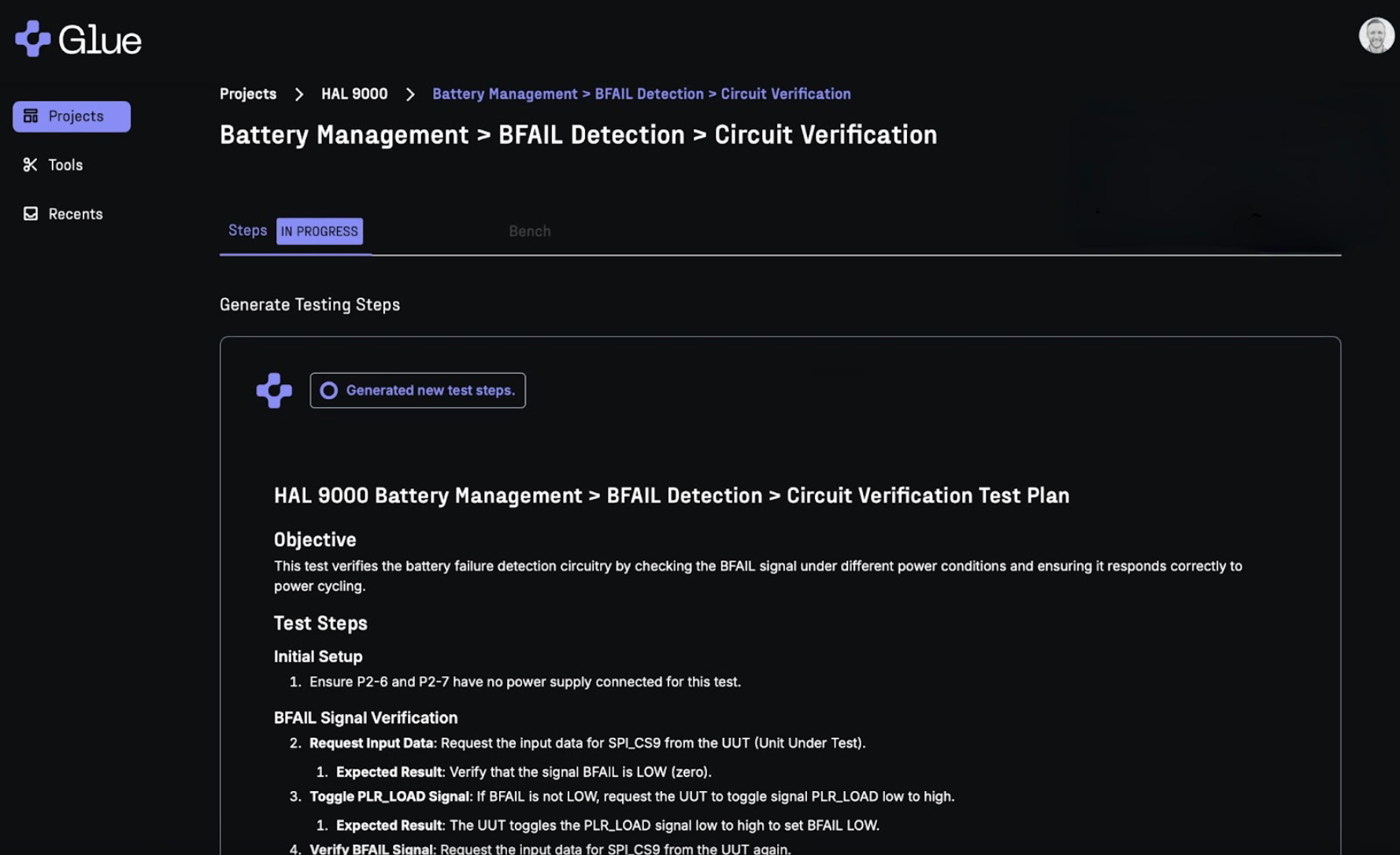

We automate the entire process of mapping features, requirements, and constraints into structured test plans. Instead of engineers manually figuring out which instruments to use, our system intelligently selects the best tools based on performance, availability, and capability. Test plans that once took hours or days can now be generated in minutes, adjusted instantly, and fine-tuned with both human expertise and machine intelligence. Whenever possible, we automate execution through our deep understanding of programmable interfaces.

Life in a Day

As a Founder and CEO, my role shifts depending on what the company needs most. Some days, I’m talking to investors and studying market trends. Other days, I’m with customers, figuring out where they struggle and how we can help. I spend time with engineers, learning about their latest breakthroughs, and explore new markets where Glue needs a stronger presence.

A startup forces you to do whatever's necessary, but that’s also the best part—I get to work with great people who turn ideas into real progress. The goal is always the same: build things that make life easier for the people who create. Compared to Tektronix, the biggest difference is speed. The problems change faster, the stakes feel higher, and the work is more varied.

Technical Achievements & Challenges

Some of Glue’s biggest technical breakthroughs have come from orchestrating large language models with advanced knowledge graphs to process massive product specification datasets and validation instrument inventories—all running seamlessly in the background. The result is a simple, intuitive interface for building and refining robust validation and verification plans.

Our biggest challenge right now is developing models that guarantee mathematical correctness and traceability in test plans. At the same time, we’re iterating on cutting-edge models that are constantly evolving. We’re moving fast, but so is AI, and keeping up with that pace is one of the hardest—and most exciting!—parts of the job.

Ideal Hardware Testing Stack

I’ve used a lot of hardware testing instruments, especially during my time at Tektronix. My ideal test setup reflects the same challenges Glue is trying to solve—dealing with a mix of vendors, each with their own automation ecosystems, making integration and usability more complicated than it should be.

For power testing, I like Keysight’s N6705C for programmable DC power and Chroma’s 63206A for DC loads—both excellent, but running on entirely different automation frameworks. Keithley’s DMM6500 or 7510 are my go-to for power analysis and debugging, and while Keithley also makes solid alternatives to Keysight and Chroma, swapping instruments just for better software integration isn’t always practical.

For signal generation and analysis, the Tektronix 6 Series B MSO is my favorite, with the MS05 as a solid all-purpose backup. Tek also makes the best time domain reflectometer in my view. And for quick checks, I always keep a Fluke multimeter and a FLIR thermal camera on hand.

In the end, my bench has about seven instruments from four or five vendors—best-in-class choices, but not built to work seamlessly together.

Q&A

Top Tech. Innovations You Admire

I might sound like a Tektronix fanboy, but they honestly pioneered some of the most impactful technologies of the last century. Their advancements in the cathode ray tube brought real-time visualizations to monitor electronic signals to see the invisible. That changed everything, opening up new possibilities for electronic hardware.

Favorite Interview Question

“Assume lawmakers in a major metropolitan area implement a new law that requires vehicles to have their headlights on when driving through a construction zone. How would you go about determining the additional energy consumption from this new law?”

I like this type of question because it pushes the interviewee to explore different variables and there’s no perfectly right answer, just a process of refining and discovering what works best.

If you want to learn more about Glue, connect with David on LinkedIn or reach out at david@gluestudio.com