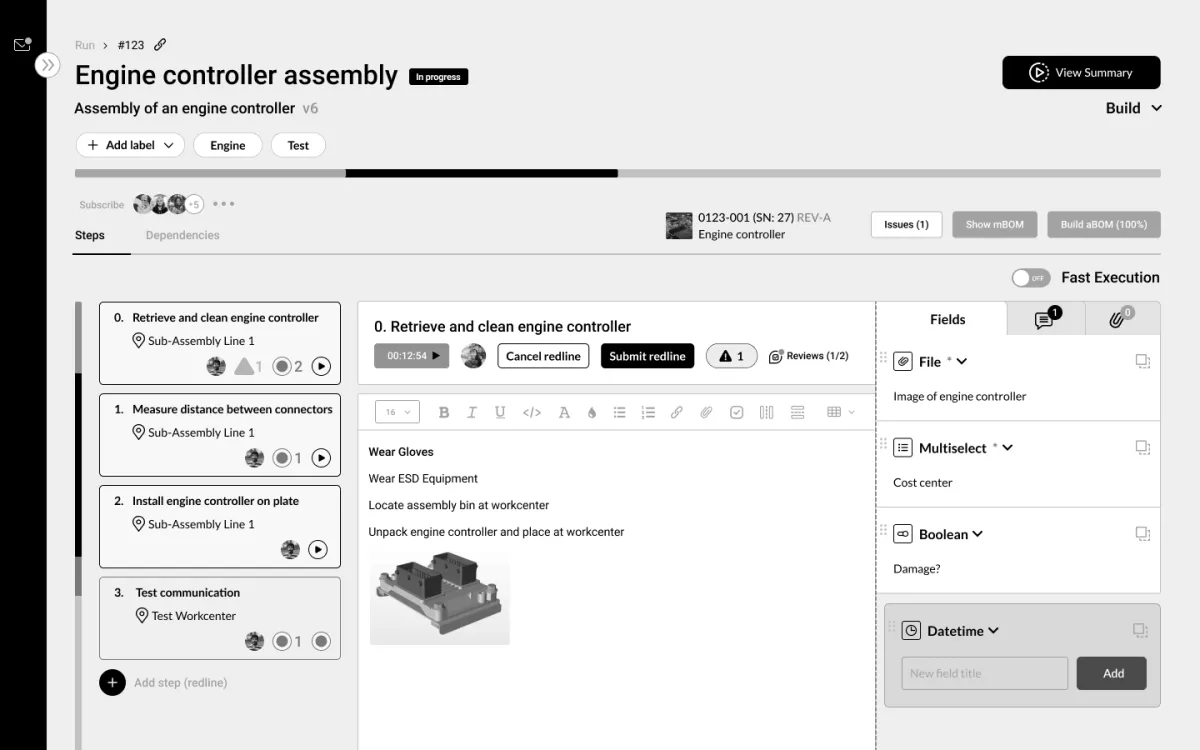

ION Factory OS by First Resonance (left), Co-founder & CEO Karan Talati (right)

This week we had the opportunity to sit down with Karan to talk about about his background, pitfalls in legacy factory software (MES, ERP), and approach to building software for the new age.

Background & Experience

I grew up in the suburbs of Chicago and went to the University of Illinois at Urbana-Champaign to study mechanical engineering. It's a great school, especially for engineering. It was a pretty big shift to get an amazing opportunity to intern at SpaceX, at that time, a little-known rocket factory in LA. I had no idea that I would be moving to Hollywood, but it couldn't have been a better decision.

I ended up getting to SpaceX at the right time – when we were setting up to grow from our first flight of Falcon 9 V1.1 into multiple flights and launch and reusability since then. I got a little bit tired by the bureaucracy that aerospace can bring, so I ran away from it for a few years and went heads down in data science and machine learning at a startup called Sense360 here in Los Angeles.

When I saw my former colleagues and peers go on to start and lead companies in the next generation of hardware building on top of SpaceX's platform, I knew that this industry would need infrastructure to be successful and that's when I started First Resonance.

Experience at First Resonance

What is First Resonance?

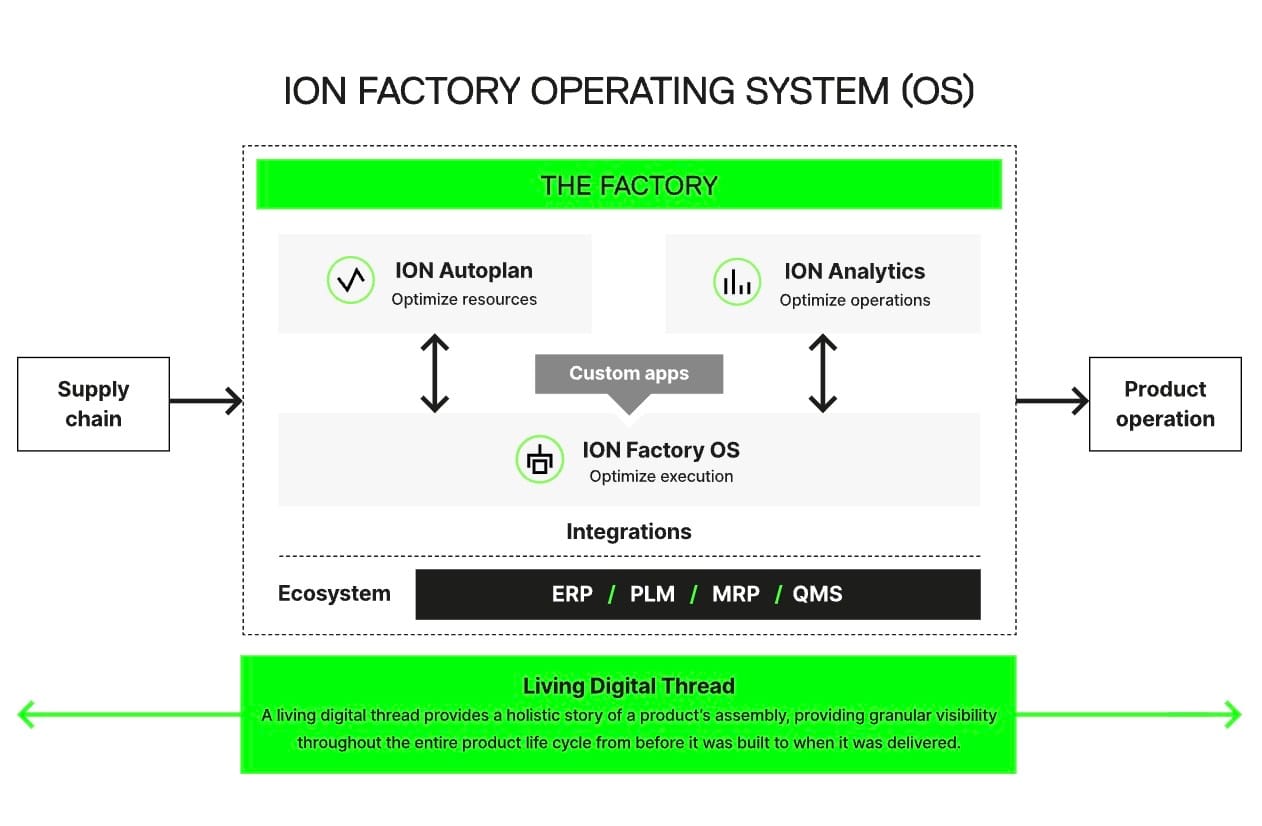

First Resonance is building a factory OS. You can think of it as a blend between MES and ERP that is fit for bringing together parts and processes in a way that's necessary for modern hardware companies.

Our software platform helps manufacturers streamline complex processes by providing accurate data, enabling informed decision-making, and managing the timely procurement and routing of parts for building intricate hardware like satellites, rockets, and nuclear reactors.

A Manufacturing Execution System (MES) is like a smart manager for a factory. It helps keep track of everything happening on the factory floor, making sure that machines and workers are doing their jobs efficiently. It collects and analyzes data in real-time to improve production, ensure high quality, and manage resources effectively. An ERP (Enterprise Resource Planning) system is like a super-organized brain for a company. It helps different parts of the business (like finance, HR, manufacturing, and sales) work together smoothly by sharing information in one central place. This makes it easier for everyone to plan, manage resources, and make decisions efficiently.

Legacy systems like SAP differ from us where we're building a modular software platform that enables a more open, flexible approach to building hardware products.

Life in a Day

My day-to-day running a startup is vastly different from my time at SpaceX and unlike anything I've done before. Startups evolve every six months, and that's been true for me as well. Initially, building a startup meant creating everything from scratch with no existing infrastructure. This included developing software that could scale to match our vision. Over time, this role expanded from just building the software and product, as well as defining the strategy, to more operational tasks like fundraising, managing investor relations, and board management.

This is a stark contrast to my time at SpaceX, where my focus was deeply technical and grew more so over time. Uniquely, SpaceX allowed me to sharpen both my practical business approach and technical skills, unlike many companies that strip away the technical edge from their employees. The work and people at SpaceX are truly magical, and nothing compares to that experience. However, starting a startup is ten times more challenging for various reasons, primarily related to organizational design and personnel management.

Aligning people, hiring the right talent, and making tough decisions are far more complex than solving deep technical problems.

Unexpected Customer Outcomes and Current Challenges at First Resonance

Some of the most interesting and unexpected customer outcomes have been quite pleasant. We often hear stories from customers about how ION is driving great results for their own clients. For example, many of our customers work directly with the DoD or DoE, and hearing about how ION's data or automation capabilities empower their workflows is amazing, especially considering how traditional these organizations can be.

One of the major challenges we're facing is that many of our customers are scaling much faster than we or the tech venture ecosystem had anticipated. When we started First Resonance, we expected to see a new class of aerospace companies, but we didn't foresee the societal shift in perception on nuclear power. Aerospace is accelerating faster, and defense tech is growing quickly due to global and geopolitical changes, as well as legislation like the IRA and the CHIPS Act. As a result, our customers are demanding much more from our services and platform than we had expected.

This means we need to be more than just a product or software vendor; we need to act as a full consulting arm. The good news is that this allows us to provide much more value to our customers. The bad news is that, as a resource-constrained startup, meeting our customers' high expectations is a significant challenge.

Ideal Software Stack for Manufacturing

The ideal software stack for a manufacturing business depends on its phase and other factors. A key element is that it must serve the company effectively. It should be interoperable, integrating various best-in-class systems to handle specific tasks. It should also provide a data platform that uses machine learning and AI, enabling the company to fully leverage its data.

An ideal stack should use AI and ML to help manufacturers make proactive decisions within their workflows. Interoperability is crucial for both legacy companies and new-age startups. If a legacy company lacks interoperability, it will struggle to upgrade its digital operations effectively, falling behind new-age competitors.

There's been an evolution away from the traditional, rigid style of software procurement. Manufacturers are no longer moving linearly from CAD to PLM to ERP to MES. Instead, they are adopting more flexible and agile system, which can be integrated regardless of whether an ERP is already in place or will be implemented later. This interoperability allows manufacturers to make decisions based on their business needs and financial situation, facilitating a more adaptable and efficient operation.

To learn more, check out Karan's webinar with Arena (PTC) and Dataum

Q&A

Favorite Invention

The introduction of interchangeable parts revolutionized manufacturing, enabling quick line changeovers and boosting production capacity, especially during World War II. These are the kind of unsung advancements that deserve more recognition.

I recommend reading Freedom's Forge for the story and details on the industrial revolution meeting WWII-era production.

Freedom's Forge

"Freedom's Forge" chronicles how American industry and innovation rapidly transformed to support the massive production demands of World War II.

Favorite Interview Questions

Two parts.

- If this job were to not work out, why would that be? And if this does work out, what does this set you up for in the future?

If you're interested in learning more about First Resonance, stay in touch through Twitter or LinkedIn.